AMUT Stretch Film Extrusion Lines | High-Speed Cast Film Systems with Zero Scrap Recovery

High-Speed Production with Zero Scrap Waste

AMUT’s cast extrusion lines for stretch film are designed for ultra-fast production, precise material handling, and in-line scrap recovery. Manufactured in Italy and supported in defined U.S. territories by Extrudamerica, these systems meet the demands of high-output film producers with minimal waste and outstanding roll quality.

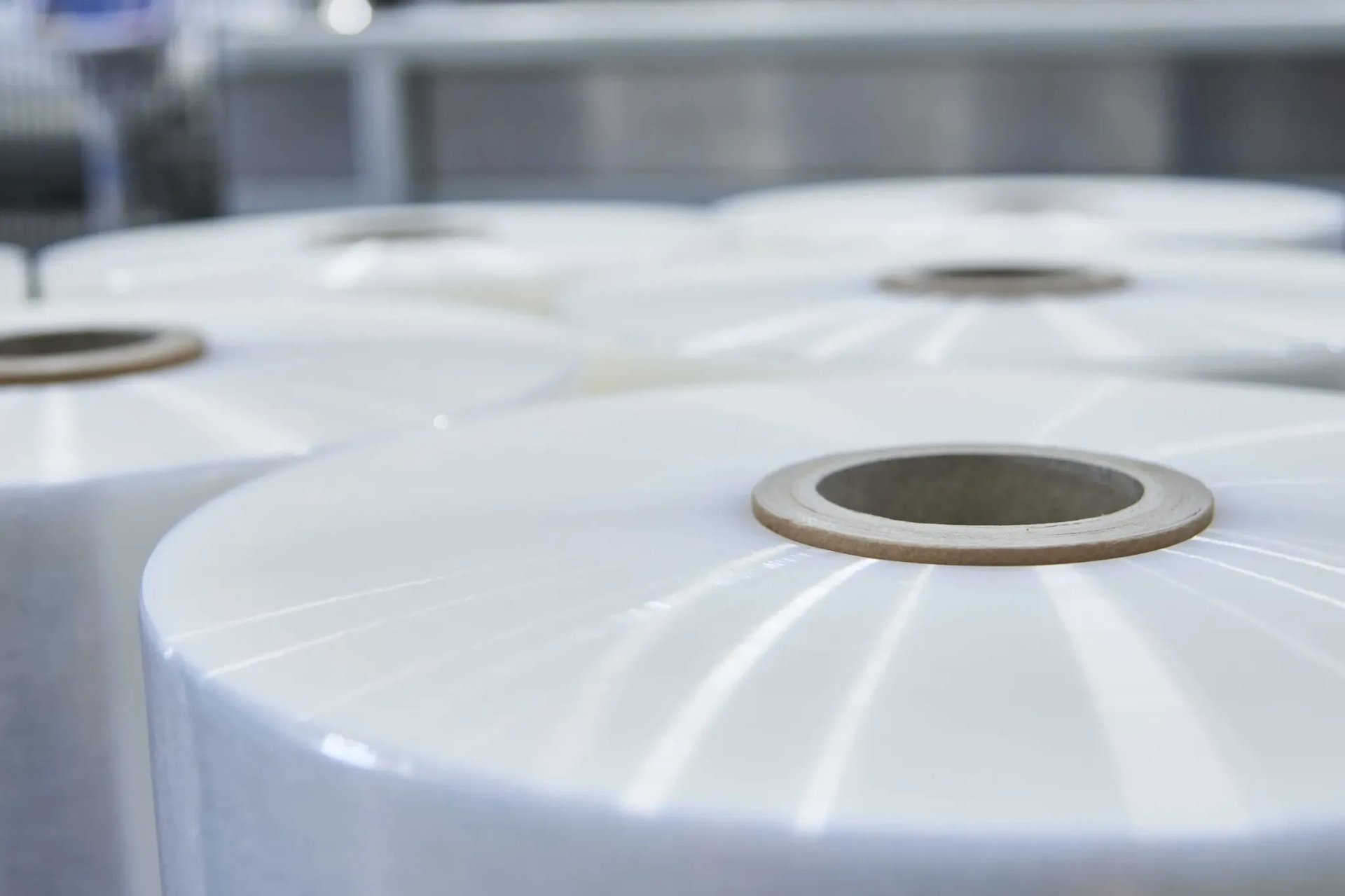

Capable of speeds over 800 meters per minute, AMUT lines process Standard, Power, Super Power, and Stiff stretch films with high winding quality and consistent thickness. Designed for both wrapping and silage applications, each line configuration is adaptable to client recipes and polymer selection.

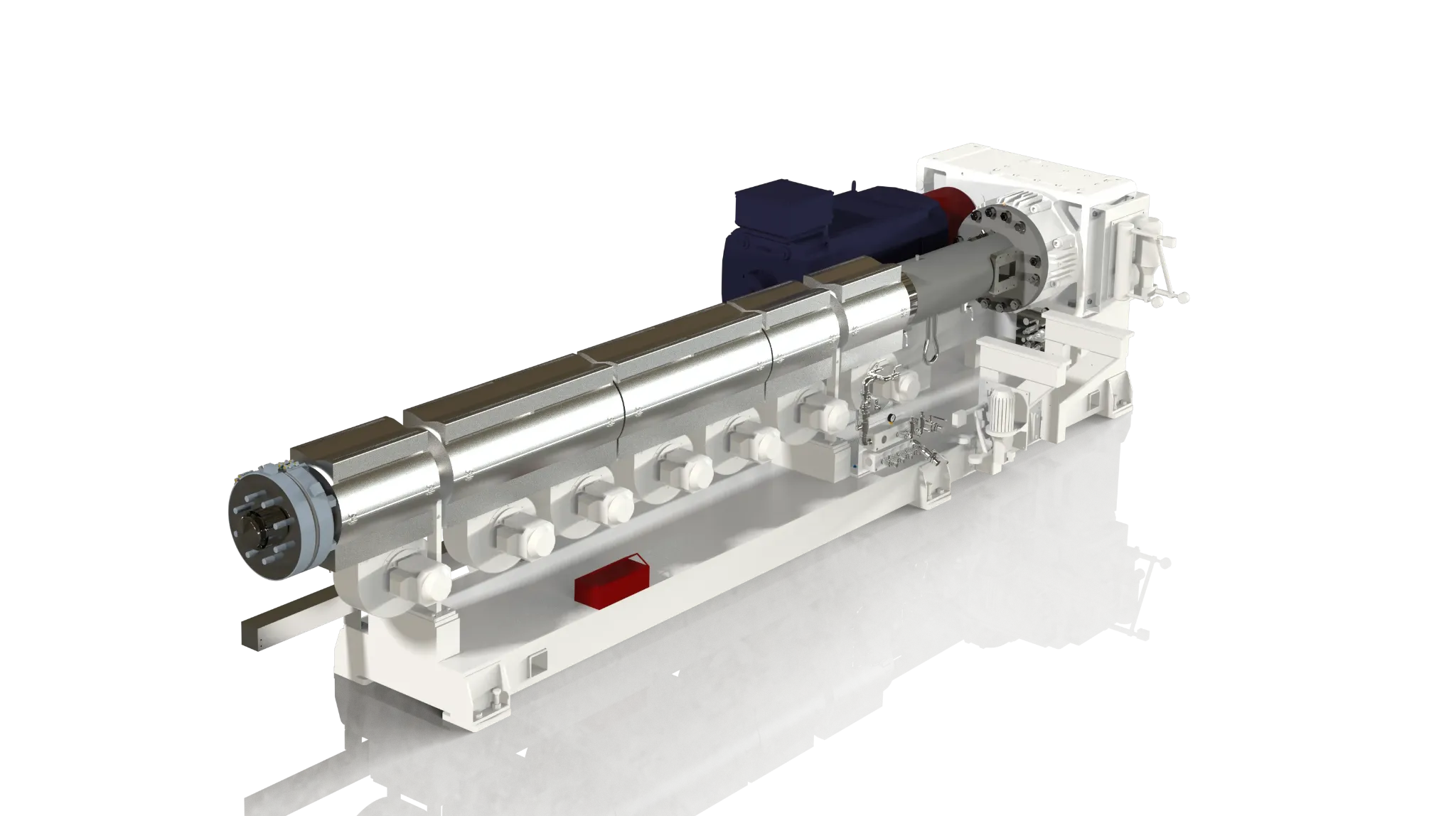

The exclusive ZERO SCRAP system enables full reclaim of startup and trim material into the main extruder—100% closed-loop—with no dust or external bags. Combined with the ROTO-FEED reclaim unit, this cold-process integration minimizes energy consumption and ensures gel-free film, all with just 5 kW of installed power.

Compact Footprint, Intelligent Winding, Seamless Integration

AMUT stretch film systems prioritize efficient plant layout, offering a compact machine footprint without compromising capacity. Their customized extruders (40 L/D and 35 L/D) include ceramic or infrared heating and water-cooled drives for high throughput and energy efficiency.

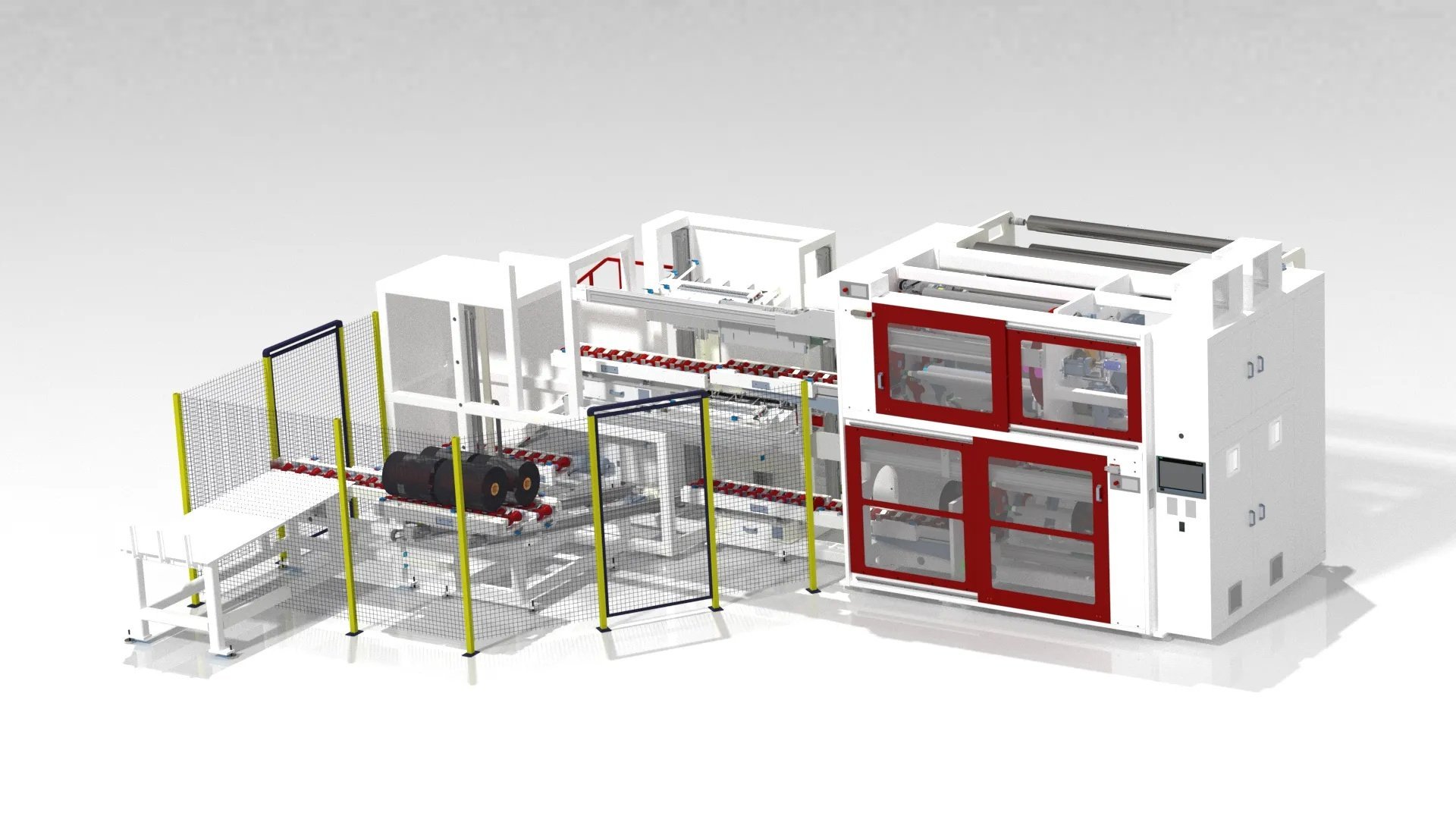

The PROWIND winding system delivers slit-in-line hand, machine, and jumbo rolls with perfect geometry and no tail. Designed for easy changeovers between 2” and 3” cores, the winder includes:

No pneumatic or hydraulic components

Electrically adjustable contact roll pressure

Individual roll weighing and in-line verification

Automated core handling with simultaneous loading and individual unloading

Finished rolls are processed through the optional Roll-Pack Unit, which automates packaging, box handling, palletization, and (in Model 2) automatic pallet storage. Learn more about AMUT’s global engineering capabilities and company history on our AMUT corporate overview page.

Designed in Italy. Represented in Select U.S. Markets by Extrudamerica

AMUT’s stretch film technology reflects decades of collaboration with polymer suppliers and film producers, culminating in highly adaptable, precise production systems.

Each system includes:

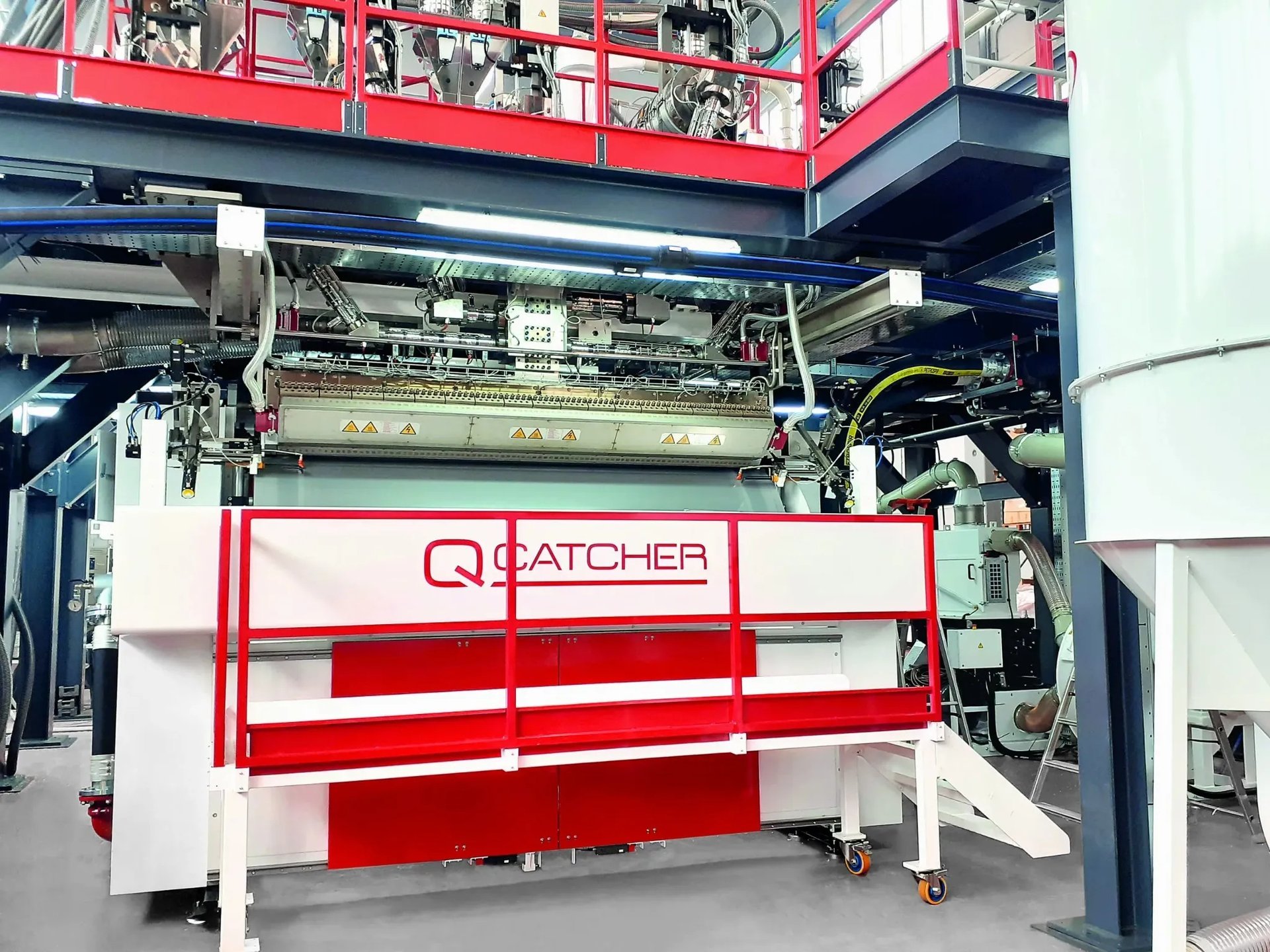

The Q-CATCHER system, which auto-recalls ideal film settings during production restarts

Proprietary flat die and feedblock systems with optimized resin flow

Twin chill rolls with web edge guide and integrated thickness gauge

Electrical enclosures in a climate-controlled upper-level container

SURVEYOR dual-control interface, compliant with Industry 4.0 standards for smart automation and operator-driven efficiency

AMUT SpA manufactures these systems in Novara, Italy.

Extrudamerica LLC is the official AMUT sales representative for specific U.S. territories, offering localized guidance, technical consultation, and support from its New Jersey headquarters.

Please see the PDF literature and videos below for expanded details.

Contact EXTRUDAMERICA now for further information or a quotation!

7-Layer high speed cast film line for the production of hand, machine and jumbo rolls

AMUT ACS 2000 Power Cast system with up to 850 m/min winding speed and 1600 kg/h output. Handles 2” and 3” cores, hand and machine rolls.

ROLL PACK - PACKAGING SYSTEM FOR STRETCH FILM ROLLS

Fully automatic packaging for hand, machine, and jumbo rolls. Includes box forming, palletizing, and optional automatic pallet handling.

CO-EXTRUSION CAST LINE FOR STRETCH FILM

6 extruders, 7 layers. Produces machine rolls (3") at 800 m/min and hand rolls (2") at 750 m/min with up to 1500 kg/h output.

CO-EXTRUSION CAST LINE FOR STRETCH FILM (LLDPE)

5-layer configuration with 4 extruders. 750 m/min speed, 1100 kg/h output. Automatic die and high-speed winder.

CO-EXTRUSION CAST LINE FOR STRETCH FILM

LLDPE-based 5-layer line with automatic die, jumbo chill roll, and ACP 1500 4-axis winder. Max roll Ø 420 mm.

CO-EXTRUSION CAST LINE FOR STRETCH FILM

7-layer super power stretch film at 1000 m/min, 1600 kg/h output. 3-level vertical layout with twin chill rolls and low-energy 40 L/D extruders.

CO-EXTRUSION LINE FOR CPP FILM

4-layer CPP film line with 2.1 m width, compact 120 m² layout. Rotary arm winder, depression air blade, and multi-manifold die.