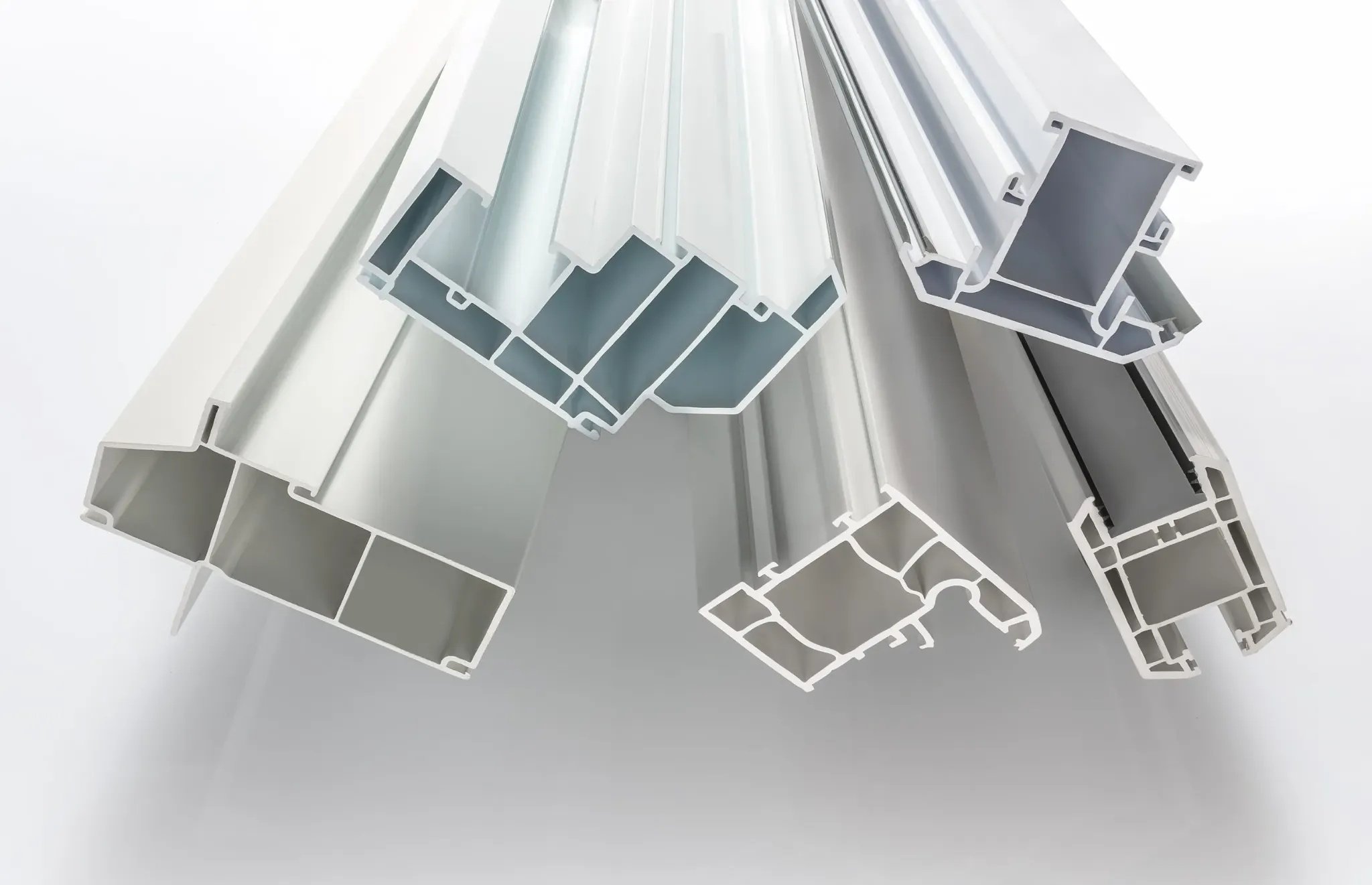

AMUT Profile Extrusion Systems for PVC, WPC, and Technical Applications

AMUT delivers advanced technology and proven reliability for the production of thermoplastic profiles. Beyond standard machines, AMUT offers complete, customized profile extrusion lines designed to meet specific customer requirements while ensuring high performance and competitive pricing. These extrusion lines are capable of producing profiles of various dimensions across a wide range of applications.

Materials and Applications for AMUT Profile Extrusion Lines

PVC :

Building industry: windows, gaskets, doors, rolling shutters, gutters, fencing, spacing joints, thermal breaking

Furnishing: furniture edgebands, decorative coatings. For specific information about these applications please see our AMUT Edgebanding Extrusion Systems page.

Industrial: technical profiles, expanded foam profiles

PA (Polyamide): Thermal joints

WPC (Wood Plastic Composites): Profiles using PO or PVC polymers combined with wood flour, rice husks, sugar cane, hemp, and other natural fibers. AMUT has developed a direct extrusion process for these applications.

EPS (Expanded Polystyrene): Frames

PO (Polyolefins): Solid and hollow profiles for construction, furnishing, packaging, and more

PMMA and PC (Acrylic and Polycarbonate): Profiles for indoor and outdoor furnishing and technical applications

TPR (Thermoplastic Rubber): Co-extruded gaskets for windows, doors, and automotive use. For flat gasket sheet some applications are served on our AMUT Sheet, Foil, and Cast Film Extrusion Systems page.

ABS (Acrylonitrile Butadiene Styrene): Profiles for electrical appliances, automotive parts, and industrial uses

Recycled Material Applications

Pipes

Profiles

Foils

Sheets.

Please see the PDF literature and videos below for expanded details. Contact EXTRUDAMERICA now for further information!

AMUT Profile Extrusion Systems Video Playlist showing a variety of lines producing the following profiles:

• Thermal Breaking

• WPC (Wood Plastic Composite)

• Flex PVC / Water-Stop

• Edgeband

• PP Co-Extrusion

• U/PVC & F/PVC Co-Extrusion

• PA Thermal Breaking

• PVC Window