AMUT Pipe Extrusion Lines

Full-System Solutions for PVC, PE, PEX, and Multilayer Pipes, Designed for U.S. Pipe Manufacturers

Overview of AMUT Pipe Extrusion Systems

AMUT offers turnkey pipe extrusion solutions for polyolefin and specialty applications, supporting U.S. manufacturers with full automation, energy efficiency, and custom-engineered processing lines. System configurations include:

- Pressure and sewage pipes (PE, PP)

- Drip irrigation tubing (LDPE, EVA)

- Hot and cold water PEX pipes

- Sound-insulated discharge pipes

- Electrical conduit, including dual-layer

- Bi-oriented pipes for shotgun cartridge production

- Flexible garden hose and braided tubing systems

- And many other applications for virtually all kinds of pipe

PVC Pipe Extrusion for Civil and Industrial Use

AMUT's PVC extrusion lines are designed for high-speed, high-output manufacturing:

- Smooth and corrugated pressure pipes

- Sound-insulated drain pipes

- Conduits for hot and cold potable water

- HVAC and exhaust vent piping

- Compatible with lead-free or tin-based stabilizers

- Complete with belling and socketing automation

5-Layer PEX and Multilayer Pipe Systems

AMUT supports multilayer pipe production using co-extruders and integrated heads:

- 5-layer heating/cooling pipes (PE-X/Adhesive/EVOH)

- Cross-linkable PE systems with online curing

- Tailored output for radiant heating and geothermal grids

Drip Irrigation Tubing Lines

Precision extrusion for agriculture and landscaping:

- LDPE or EVA-based systems

- High-accuracy emitter insertion (inline and punched)

- Optional UV and striping systems

- Servo-driven winder and cutter integration

Polyurethane Foam Insulated “Pipe-in-Pipe” Conduits

AMUT's insulated conduit lines produce flexible and rigid outer pipes with internal water or electric service tubing:

- Used for telecom, fiber optic, and plumbing

- Supports PU foam core or air gap insulation

- Multi-step production with inline bundling

Garden Hose and Braided Tubing Systems

Flexible extrusion lines for reinforced hose:

- PE or soft PVC base with polyester braid integration

- Options for single-layer and coextruded designs

- Cooling baths, winders, and take-off stations included

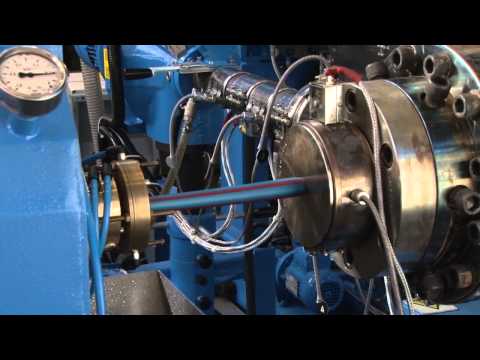

Precision Pipe Heads and Cross-Heads

AMUT offers a complete range of pipe heads (U.S. term: dies), including:

- TEAT: Engineered for ABS, UPVC, FPVC and other materials

- TEX: Spiral mandrel, HDPE/PP

- TEPO: Low-resistance flow design for PEX and PE, PA and PP

- TECO: High-throughput, multilayer, foam-compatible

Also available:

- Cross-head dies for multilayer and conduit production

- Configurable tooling to match North American standards

Applications by Material: PE, PVC, PP, PEX, PA

- PE: Gas and water mains, irrigation, sewer

- PVC: Pressure and drain lines, building systems

- PP: Hot/cold water and chemical waste

- PEX: Underfloor heating, sanitary water

- PA: Brake systems, compressed air, specialty tubing

Request a Custom Configuration

Call Extrudamerica LLC at 973-696-0445 or email us for a tailored quote on AMUT pipe extrusion equipment.

📘 AMUT 5-Layer PEX Pipe Extrusion Lines Brochure | EXTRUDAMERICA LLC

📘 AMUT Drip Irrigation Tubing Extrusion Lines Brochure | EXTRUDAMERICA LLC

📘 AMUT PU Insulated Pipe-In-Pipe Extrusion Lines Brochure | EXTRUDAMERICA LLC

📘 AMUT Crosshead Pipe Extrusion Dies Brochure | EXTRUDAMERICA LLC

📘 AMUT TEX & TEPO Pipe Extrusion Dies Brochure | EXTRUDAMERICA LLC

AMUT Pipe Extrusion Line VIDEOS | EXTRUDAMERICA LLC

UPVC PIPES EXTRUSION LINE RANGE 63-220 MM, OUTPUT 600 KG/H BASED ON TWIN SCREW EXTRUDER

The AMUT line is designed to extrude rigid pipes in uPVC suitable for pressure and sewage purpose, pipes in uPVC, with diameters ranging from 63 mm up to maximum 220 mm and an over; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF UPVC CORRUGATED PIPES

EXTRUSION LINE FOR THE PRODUCTION OF UPVC CORRUGATED PIPES Technical Features: Application: flexible electric conduit pipes Range of diameters: from 16 to 32 mm Output: 150 kg/h us; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF UPVC PIPES

EXTRUSION LINE FOR THE PRODUCTION OF UPVC PIPES Technical Features: Application: water supply and drainage pipes Range of diameters: from 63 to 125 mm Output: 350 kg/h using parall; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF HDPE PIPES

EXTRUSION LINE FOR THE PRODUCTION OF HDPE PIPES Application: HDPE pipes with small diameter range Range of diameters: from 16 to 63 mm Output: 250 kg/h using single screw extruder; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF SPIRAL PVC HOSES

EXTRUSION LINE FOR THE PRODUCTION OF SPIRAL PVC HOSES Material: PVC (Rigid and Flexible) Based on N.2 Single Screw Extruders – EA48 Model Pipe Ø: from 10 to 50 mm Double Exit Pr; More info shown when played.

EXTRUSION LINE FOR BIG SIZE MULTILAYER PPR PIPES WITH GLASS FIBER

EXTRUSION LINE FOR BIG SIZE MULTILAYER PPR PIPES WITH GLASS FIBER Diameter up to 630 mm for the production of multilayer-pipes in PP with glass fiber: this is the line sold by AMUTThe; More info shown when played.

EXTRUSION LINE FOR PP-R MULTILAYERS PIPES PRODUCTION

EXTRUSION LINE FOR PP-r MULTILAYERS PIPES PRODUCTION Range of diameters: 20 to 160 mm (PN20-PN25) Output: 700 kg/h Layers Configuration: A-B-A, A-B-C with external coloured stripes; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF HDPE PIPES

EXTRUSION LINE FOR THE PRODUCTION OF HDPE PIPES Faetures: Pipe Ø: 110 - 500 mm Output: 1200 Kg/h Extruders: n.1 single screw extruder, model EA 130 n.1 single screw co-extruder,; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF MEDICAL TUBING

EXTRUSION LINE FOR THE PRODUCTION OF: - 3-layer PP pipes for medical application; - single layer LDPE pipes for cosmetic application (soap dispenser) Caratteristiche: Layers config; More info shown when played.

HDPE PIPES EXTRUSION LINE

HDPE PIPES EXTRUSION LINE FEATURES: Pipes: HDPE Outer Ø 6.8 mm Thickness 3.9 mm FLEXIBLE PVC Outer Ø 6.8 mm Thickness 4 mm With its wide range including various technical solutions,; More info shown when played.

HDPE PIPES EXTRUSION LINE

HDPE PIPES EXTRUSION LINE Extrusion line producing PE100 pipes, small size Pipe outer diameter: 20 - 63 mm Line speed: up to 50 m/min Output: 240 kg/h FEATURES: - n.1 single screw-; More info shown when played.

SINGLE LAYER HDPE AND 3-LAYER PPR PIPES EXTRUSION LINE

SINGLE LAYER HDPE AND 3-LAYER PPR PIPES EXTRUSION LINE Line for the production of both kind of pipes, multilayer PPr with glass fiber and HDPE pipes for drinkable and hot water and-; More info shown when played.

PPR + GLASS FIBER MULTILAYERS PIPES CO-EXTRUSION LINE

PPr + GLASS FIBER MULTILAYERS PIPES CO-EXTRUSION LINE FEATURES: Pipes Dimensions: from 20mm to 160mm (PN20 - PN25) Structure: A-B-A or A-B-C A - Outer Layer, PPr B - Middle LayerWith; More info shown when played.

PPR MULTILAYERS PIPES EXTRUSION LINE

PPr MULTILAYERS PIPES EXTRUSION LINE FEATURES: Pipe Ø: from 20mm to 1600 mm (PN20 - PN25) Structure: 3 layers A-B-A or A-B-C A - Outer Layer, PPr B - Middle Layer, PPr + Glass Fib; More info shown when played.

MULTILAYER AUTOMOTIVE PIPE CO-EXTRUSION LINE

MULTILAYER AUTOMOTIVE PIPE CO-EXTRUSION LINE FEATURES: 5-LAYERS: Base Polymer Bonding Layer Barrier Layer Bonding Layer Base Polymer PROCESS MATERIAL: PA12 -- PA6.6 -- PVDF - POM; More info shown when played.

C-PVC & U-PVC TWIN PIPE EXTRUSION LINE

C-PVC & U-PVC TWIN PIPE EXTRUSION LINE FEATURES: Pipe Ø 16mm to 63mm Extruder: BA92 twin screw Output: C-PVC pipes 500kg/h, U-PVC pipes 700 kg/h; More info shown when played.

PVC PIPES EXTRUSION LINE

PVC PIPES EXTRUSION LINE FEATURES: BA125/28D -- Twin screw extruder 110kw motor Dosing unit and loading unit for vergin material Dosing unit and loading unit for regrind Temperatu; More info shown when played.

BIORIENTATED PIPE_SHOTGUN SHELLS EXTRUSION LINE

BIORIENTATED PIPE_SHOTGUN SHELLS EXTRUSION LINE FEATURES: Extruder: EA48 (L/D 33) Pipe Ø: from 11 mm to 22mm Thickness: 0,5mm - 0,6mm (depending of the application) ExtrusiSince; More info shown when played.

HDPE PIPES EXTRUSION LINE

HDPE PIPES EXTRUSION LINES FEATURES: Width: 1.000mm Output: 1.600 kg/h Pipe Ø: up to 1600 mm With its wide range including various technical solutions, AMUT's production does not only; More info shown when played.

F/PVC BRAIDED PIPES EXTRUSION LINE

F/PVC BRAIDED PIPES EXTRUSION LINE FEATURES: Single screw extruder EA70 Cooling unit Braiding unit Heating unit Coating extrusion head Cutting unit Winder unit; More info shown when played.

F/PVC KNITTED PIPE EXTRUSION LINE

F/PVC KNITTED PIPE EXTRUSION LINE FEATURES: 5 layers co-extrusion die Drying system Two haul-off units TS80 Knitting machine Pipe tensioning check Pre-heating oven Coating head Coo; More info shown when played.

MEDICAL TUBING EXTRUSION LINE

MEDICAL TUBING EXTRUSION LINE AMUT lines are able to satisfy the medical tubing industry requests: - high output - best quality - dimensional precision - reduced tolerance in pro; More info shown when played.

EXTRUSION LINE FOR THE PRODUCTION OF SHOTGUN SHELL

The biorientation technology allows increasing some performances of the thermoplastic material. Its use applied to the extrusion of HDPE pipes allows the production of thin wall pipes; More info shown when played.

EXTRUSION LINE TO PRODUCE SHORT CUT LENGTHS PIPES

PE and PP pipes with range of diameters from 16 to 63 mm. Thickness range from 2 to 6 mm. Productivity up to 35 m/min. Main extruder single screw Ø 60 mm - 40 L/D Co-extruder, si; More info shown when played.

VIDEO SHOT SHOW 2023 SHORT

The biorientation technology allows for performance enhancement of the thermoplastic material. Its use applied to the extrusion of HDPE pipes allows the production of thin wall pipes; More info shown when played.